3D Printing and prototyping

Accelerate Product Validation with Rapid 3D Printing and Prototyping

Blue Ridge’s 3D printing and prototyping services bring your concepts to life—fast. Our experienced team helps you validate fit, form, and function before any tooling is started, drastically reducing the risk and cost of design changes. By merging rapid prototyping with our engineering expertise, we set the foundation for a smooth transition long-term, efficient production.

Key Benefits

Faster Time-to-Market: Rapid prototyping can collapse multiple design cycles into one streamlined workflow, giving you a critical edge in competitive markets.

Data-Informed Refinements: Combine hands-on testing with real-world analytics from our engineering software.

End-to-End Capabilities: Easily transition to our automated manufacturing, assembly & decorating, or fulfillment services for a complete, concept-to-fulfillment solution.

Cost Savings: Identify product issues early, reduce material usage, scrap, tooling rework, and downtime.

Why Rapid Prototyping Matters

Shorten Development Cycles: Swiftly pivot based on real-time feedback from physical prototypes—cutting down on overall design iterations.

Reduce Risks & Costs: Identify potential flaws before investing in full-scale tooling, minimizing expensive post-production tweaks.

Improve Stakeholder Alignment: Physical prototypes help everyone—from engineers to marketers—visualize the product and share a unified goal.

Our 3D-Printing Capabilities

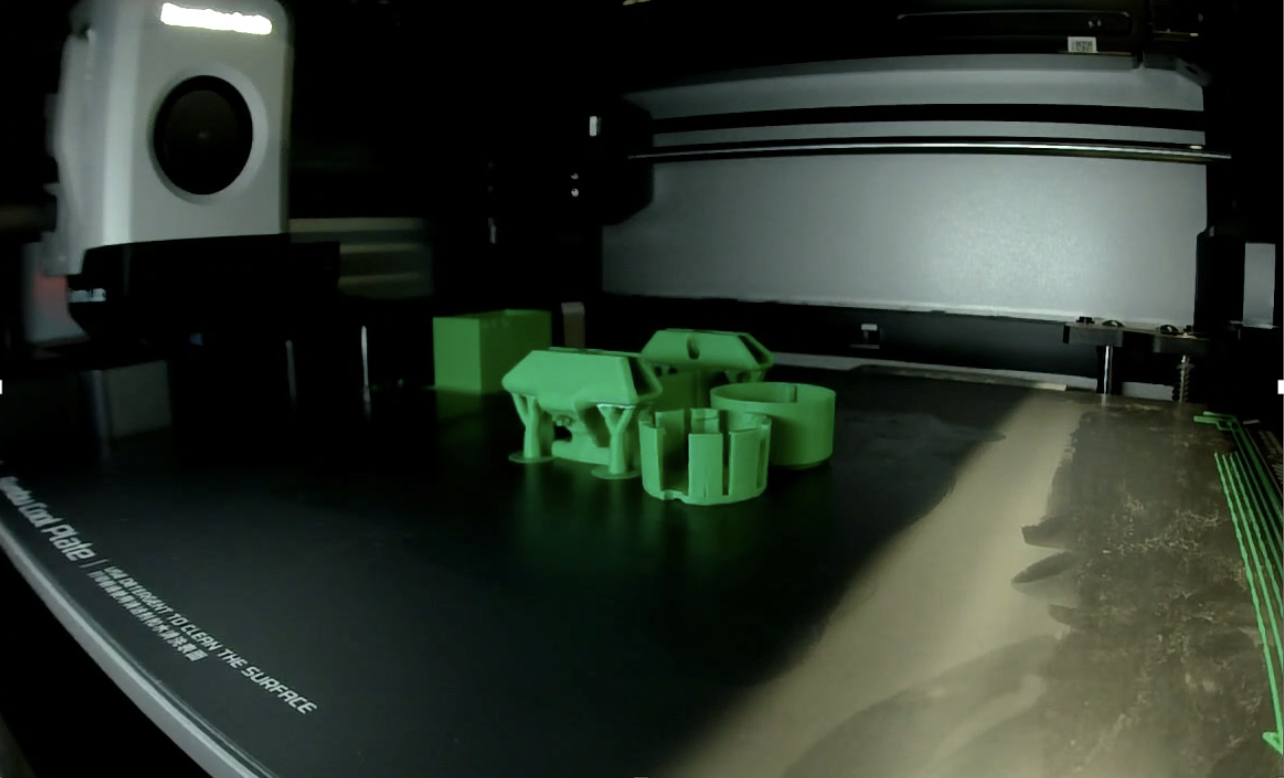

Advanced 3D Printers

We leverage industrial-grade 3D printers that leverage Multi-Jet Fusion (MJF) and Fused Deposition Modeling (FDM) technologies to build prototypes from materials from PA-12 (nylon) to ABS, PLA, and more. This flexibility ensures your prototypes match the intended look, feel, and function as closely as possible.

Functional Testing and Iteration

Want to test your part under real-world conditions? 3D-printed parts do not perform in the same way injection- molded parts do, but we can make some strong correlations and qualitative analyses. Our engineering team collaborates with you to assess structural integrity, fit, and performance. If adjustments are needed, we revise the design and reprint—within hours to days.

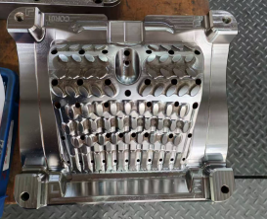

Bridge-to-Production

After finalizing a prototype, we can seamlessly shift to custom injection molding. Our early data and learnings accelerate the tooling process and ensure consistent part quality during mass production.

Real-world Applications

Our Capabilities

Let’s Bring Your Ideas to Life

From finished prototypes made for review by decision makers to multiple “what-if” design permutations, we tailor our 3D-printing solutions to meet your unique project demands. Reach out via our contact us page or submit a request a quote to see how our ingenuity-driven prototyping services can propel your next product to success.