Automated Manufacturing

Boost Efficiency and Consistency with Robotic, Data-Driven Production

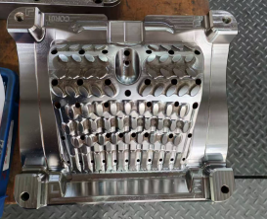

Blue Ridge’s automated manufacturing solutions offer more than just faster cycle times; they deliver unmatched consistency, real-time quality control, and flexibility for diverse market demands. By integrating 3-axis robotics, advanced sensors, and lean manufacturing principles, we minimize errors, lower labor costs, and keep production running 24/7. The result? You receive precisely molded parts, on schedule, with fewer variables to worry about.

Key Benefits

Consistent Quality: Automated lines reduce human variability and maintain strict process control.

Time & Cost Savings: By streamlining labor-intensive tasks, cycle times drop and labor costs are contained.

Scalability: Robotics and modular work cells allow for quick reconfiguration—ideal for growing product lines or pilot runs.

Integrated Services: Seamlessly combine automated manufacturing with our engineering, 3D printing and prototyping, custom injection molding, assembly and decorating, and fulfillment to handle your entire project under one roof.

Our Approach

Robotic Precision

We captialize on our robotic integration experience to create custom automation solutions for high-volume products, including machine design, PLC conveyors and bowls. This robotic precision reduces the risk of human error and ensures every part consistently meets your specifications. By automating tasks that once relied on manual labor, we free our team to focus on continuous improvements, process optimization, and overseeing the finer aspects of production.

data-driven production

Real-time data monitoring is at the heart of our automated processes. From tracking cycle times to measuring temperature fluctuations, we gather performance metrics that reveal areas for immediate fine-tuning. When anomalies occur—such as a slight variance in material flow—our system instantly flags them, allowing the production team to make rapid adjustments. This feedback loop guarantees higher yield, lower scrap rates, and a more predictable supply chain for your business.

Adaptive Manufacturing

Whether you’re producing small precision parts or larger, more robust components, our automated lines can be configured to accommodate a range of mold sizes and product complexities. This adaptability extends to new projects, where we can quickly ramp up or scale down based on your evolving needs. Combined with 24/7 operations, automated manufacturing ensures that deadlines are met, even under tight schedules or fluctuating order volumes.

Real-world Applications

Our Other Capabilities

Let’s Automate Your Next Project

Ready to unlock faster cycle times, greater consistency, and a more reliable supply chain? Our automated manufacturing solutions can be tailored to your unique specifications and production goals. Contact us or head to our request a quote page to explore how we can maximize your efficiency through robotic precision and data-driven operations.