How ultrasonic welding revolutionizes plastic assembly

Ultrasonic welding remains a foundational technology in modern manufacturing, providing a fast, repeatable, and robust solution for joining plastic components. By efficiently converting high-frequency electrical energy into mechanical vibrations, the process achieves a clean, strong, molecular bond in milliseconds, eliminating the need for messy adhesives or bulky fasteners. This blend of speed, aesthetic quality, and the ability to form hermetic seals ensures that ultrasonic welding remains the industry standard for everything from intricate consumer electronics to critical automotive components, securing its vital role in the future of reliable plastic assembly.

A New Dawn for "Made in the USA": The Resurgence of Domestic Manufacturing

After decades of outsourcing and offshoring, a powerful trend is sweeping across the U.S. business landscape: reshoring manufacturing. This movement, driven by economic shifts and a desire for greater security, is bringing back domestic manufacturing, signaling a new era for American industry and promising to create jobs, strengthen supply chains, and revitalize local economies.

Why Pad Printing on Plastic Injection Molded Parts is a Smart Solution to Part Decorating

Using a pad printer or pad printing machine, manufacturers can apply high-quality graphics, text, and symbols directly onto plastics injection molded parts with unmatched accuracy and quality.

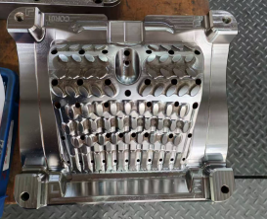

From Concept to Coop, Bringing the Coop Scoop to Life

Blue Ridge Industries worked collaboratively with Bee.Jeweled.Coop to develop a patented 2-in-1 chicken poop scoop and rake. This mold was designed by Blue Ridge Industries and is currently being utilized to produce more than 19,000 units.