How ultrasonic welding revolutionizes plastic assembly

In the world of plastics manufacturing, joining two components is a common challenge that demands a reliable, fast, and aesthetically pleasing solution. While traditional methods, such as adhesives or screws, can be messy or add bulk, ultrasonic welding plastics offers a clean, efficient, and high-strength alternative.

Ultrasonic welding is a process that uses high-frequency acoustic vibrations to create a molecular bond between two thermoplastic parts. It's a fast and repeatable process that eliminates the need for solvents, adhesives, or mechanical fasteners, resulting in a clean, strong, and virtually invisible weld. Specifically, the process involves converting high-frequency electrical energy into mechanical vibratory energy to join plastic parts. Key phases of the process include:

Vibration Generation: A converter (or transducer) within an ultrasonic welding machine changes the 50/60 Hz electrical energy into high-frequency electrical energy—in the case of Blue Ridge’s two machines, 15kHz and 20kHz. The converter then uses the piezoelectric effect, the ability of certain materials to convert electrical energy into mechanical movement, to transform this high-frequency electrical signal into mechanical vibrations.

Amplitude Modification: The mechanical vibrations are then channeled through a booster, which either increases or decreases the amplitude (i.e., intensity) of the vibrations.

Energy Delivery: The adjusted vibrations are then delivered to the top plastic part via a custom tool called a horn, or sonotrode.

Heating and Melting: The horn presses against the upper plastic part, causing it to vibrate against the stationary lower plastic part. This rapid friction generates localized heat at the joint interface, causing the plastic material at the interface to instantly melt.

Molecular Fusion: Once the vibrations stop, a clamping force is maintained for a short period of time, during which the molten material solidifies and creates a strong, permanent molecular bond between the two parts.

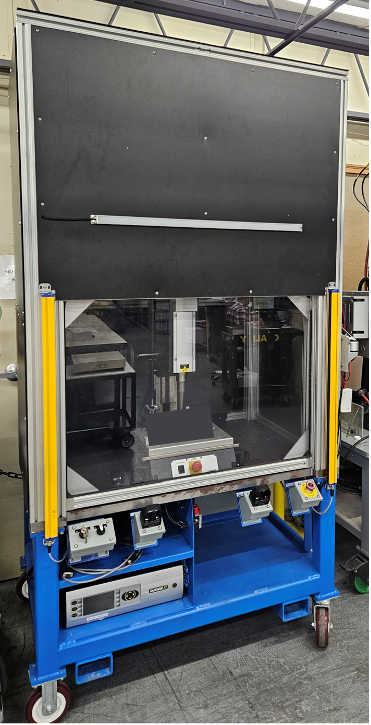

Blue Ridge Industries operates two ultrasonic welding machines.

Benefits of Ultrasonic Welding

Manufacturers choose ultrasonic welding over other methods, such as hot plate and vibration welding because of the key advantages it provides:

· Speed and Efficiency: It's often completed in milliseconds, allowing for high-volume, continuous production.

Clean and Aesthetically Pleasing: The process doesn’t require foreign materials (e.g., adhesives, screws), resulting in a clean joint line and professional finish.

High Strength and Hermetic Seals: It produces strong, reliable, and consistent welds, as well as hermetic seals (i.e., permanent, air-tight), which are critical for medical and food packaging applications.

Low Energy Consumption: Since the heat is generated internally and rapidly, the overall required energy is lower than other heat-based welding methods.

Minimal Stress: Heat is concentrated at the joint interface, minimizing thermal stress on the surrounding plastic and preventing material degradation.

Ultrasonic welding is the industry standard for high-speed, high-volume production of small-to-medium parts. Due to its precision and reliability, it's often used in automotive components (e.g., panels, lighting), consumer electronics (e.g., remote controls, chargers) and packaging (e.g., sealing blisters, clamshells).

Blue Ridge Industries uses ultrasonic welding to permanently bond plastic parts and to install metal inserts into plastic parts. Ultrasonically installed inserts can be installed much faster than using a heat staking process, with most inserts being welded in less than one second. Blue Ridge engineers have experience designing joint interfaces and sourcing inserts to meet customer requirements.

Meanwhile, due in part to its significantly slower cycle time, hot plate welding is typically reserved for the largest parts needing the maximum joint area and strength. Vibration welding serves as an effective middle ground, ideal for medium-to-large parts that are too big for ultrasonics but require a faster cycle time than hot plate welding.

Ultrasonic Welding Technologies

Ultrasonic welding systems have significantly evolved to meet diverse production needs, while retaining the same fundamental principle of operation. The most common systems are standard benchtop welders, which are manually or semi-automatically operated systems suitable for a variety of general production runs. For high-throughput manufacturing where maximum consistency and speed are paramount, automated systems integrate fully automatic welders into complex assembly lines, utilizing robotics and specialized part handling.

Specialized processes rely on other configurations, such as continuous ultrasonic welding, which is designed for ongoing processes (e.g., sealing long rolls of plastic films, fabrics, or tubing in the packaging and textile industries); and scanning welders that apply ultrasonic energy to weld large, complex contours or multiple discrete spots simultaneously.

Blue Ridge Industries operates two ultrasonic welding machines. One is a 15kHz model and the other is a 20kHz model. The ultrasonic welding process is robust and can be controlled by weld time, weld distance, or amount of energy imparted. The process is also precise with 0.5ms data acquisition for accuracy and stroke increments as small as 0.001” increments.

Authored by Adam Noble, vice president, Noble Plastics - Adam leads a cross-functional operations team in at BRI and sets the company vision and goals to guide the organization toward its 2030 Vision. He uses data and automation to improve efficiencyand works with his team to take new products from first customer contact through full production.