Contract Manufacturing and assembly

Streamline Your Production with Our Comprehensive Contract Manufacturing and Assembly

Blue Ridge’s contract manufacturing and assembly services offer a seamless extension to our custom injection molding capabilities, ensuring your products are fully prepared for the market—without juggling multiple vendors. We focus on process enhancements, lean workflows, and a family-like culture that treats every assembly or packaging task with meticulous care. As a trusted partner, we go beyond injection molding to deliver tailored solutions that optimize product management, streamline operations, and strengthen long-term relationships.

Key Capabilities

Ultrasonic Welding: Securely fuses plastic components, creating robust bonds without adhesives.

Insert Installation: Embeds metal or plastic inserts to reinforce threaded holes or attachment points.

Mechanical Assembly: Combines multiple molded and purchased components into a complete unit.

Functional Testing: Ensures each product meets operational requirements before distribution.

Point-of-sale Packaging: Preps items for immediate retail placement, maintaining a professional presentation.

Shrink Wrapping: Offers a protective, tamper-evident layer around individual products or grouped sets.

Anti-theft Tag Placement: Integrates security elements essential for retail environments.

Labeling: Delivers a polished finish with accurate, brand-consistent labeling options.

Our Approach

Integrated Post-Molding Solutions

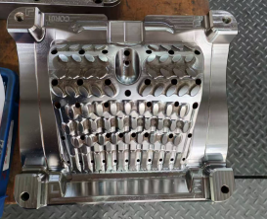

Once parts emerge from our 50–1,000 ton presses, they can move directly into assembly and packaging stations under the same roof. This single-source approach eliminates unnecessary shipping steps or coordinating with outside contractors, saving you time and reducing handling risks.

Precision Assembly and Testing

Depending on your project’s complexity, our team can perform insert installation, ultrasonic welding, and mechanical assembly to create a fully functional unit. We also conduct functional testing to confirm product performance—whether it’s a simple fit-test or more advanced operational checks.

Packaging and Security

After assembly, products can be readied for their final destination through point-of-sale packaging, shrink wrapping, anti-theft tag placement, and labeling. Each step is documented and monitored to uphold our 95% or higher acceptance rate and protect product integrity.

Sourcing and project Management

We provide seamless inventory management with real-time dashboards that track component needs, ensuring timely orders and uninterrupted production, especially for assembly products. Our just-in-time inventory support allows us to build and store products, giving customers flexibility and efficiency in their supply chain.

Real-world Applications

Our Other Capabilities

Take Your Product from Mold to Market

Ready to eliminate supply chain complexity and bring your products to market faster? Blue Ridge’s contract manufacturing and assembly services ensure every part of the post-molding process is handled with the same ingenuity and attention to detail that define our injection molding operations. Contact us or visit our request a quote page to discover how we can simplify your production and enhance your bottom line.